Bulk Bag Filling System Case Study

Bulk Bag Filling System

A nutraceutical manufacturer found new purpose for a product that had been infrequently produced previously. A bulk bag was chosen for transporting the product, in bulk, from the processing plant to customers. However, there were plant issues relating to handling this product due to its unique, challenging characteristics. An area of the plant for filling bulk bags was selected, but the best approach for filling these bags was far from clear. Selecpac USA was asked to propose a solution.

The Challenge

To accommodate the continuous flow of product to packaging, the client suggested a single fill station system that would accumulate product during the time that a filled bag was removed and replaced with an empty bag. Selecpac USA realized that the key to success of this project was addressing product handling. We systematically studied the product to understand how it was being handled at the time, along with the challenges they faced. We reviewed all the equipment solutions they had used, with little success in the past, as well as the existing system that was not meeting optimal goals. Selecpac USA concluded that there was high risk in accumulating product and proposed an alternate solution without the need for accumulation.

The Solution

The Solution

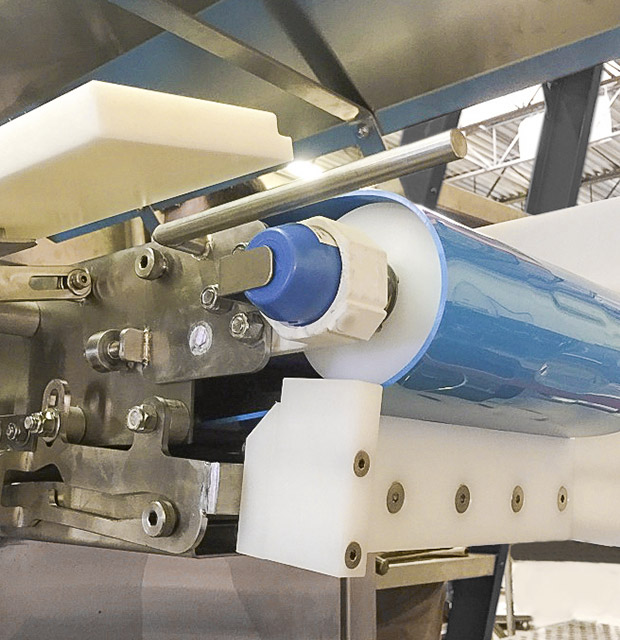

Instead, two alternating fill stations were proposed such that while Station 1 was busy filling a bulk bag, a filled bag on Station 2 could be removed and replaced with an empty bag without any interruption to the continuous flow of product. The system also featured a paddle conveyor, vision inspection, metal detection with automatic rejection of contaminated product, and sanitary stainless-steel conveyors. Selecpac USA provided all controls for a turnkey system solution including installation assistance, start-up, and training.

Although the ultimate solution was different than originally concepted by the client, the project was completed on time and in budget. Eliminating the potential headaches of product accumulation was a welcome relief for plant operations. Bulk bags were filled fast and accurately to meet the demands of the customers.